April 30, 2006

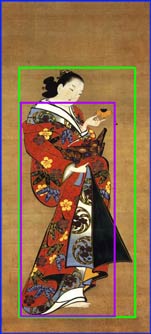

Shortly after this project got the 'green light' some months ago, I placed an order for a selection of blank woodblocks for it. I mentioned earlier that there were going to be a selection of block sizes used for this image, but until the colour separation work is done, the actual number and their dimensions isn't clear. So at that time I simply sat and studied the image for a while, and came to the conclusion that it could be done most efficiently by using blocks of three different dimensions.

To print the background area, of course blocks of at least the same size as the print are necessary. I say 'blocks' in plural, because it will need around four faces I think: one for the base tone, and three with texture carved into them.

I will need a number of blocks that match the green area on the picture. The main outline blocks (there will be two, one light one dark) of course have to be this size, and I think I'll use this dimension for the face/hair areas too (combining them on the same block as some of the kimono patterns).

Then finally, the purple outline covers the smallest ones I will use, for all the various kimono patterns.

I didn't know just exactly how many I would need, but made a rough count, and placed the order. Here is an image showing three of the blocks that arrived a couple of months ago:

They have done pretty well at finding cherry with a minimum of defects. They certainly aren't perfect, but the days of getting perfect wood are long long behind us.

To put these in scale, here's one of the larger ones sitting on my carving bench; just about the maximum I could possibly handle there, I think!

When the blocks arrived, I of course opened up the packages and gave them a quick once-over; if there were any problems I wanted to get them sorted out right away, before I got to the carving stage. But I screwed up. I checked each face carefully for defects, roughness, or splits, etc., but didn't think to closely inspect the inner plywood.

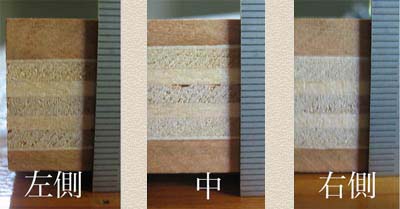

Just yesterday, when I was finally laying them out on my bench getting ready to make the choice of which particular block would be used for each colour, I found that the maker had been extremely careless during their production, and had allowed the inner plywood core to become warped during the bonding process:

It's difficult to see in that photo, but the core has a huge upward curve along the length of the block. Here's a composite shot of the left, centre, and right ends of the same piece:

The blocks themselves are totally flat and smooth, top and bottom, and if I don't look at the core, but just run my hands over the surfaces, I can't detect the problem. But having distortion like this in the inner core is unacceptable, for a number of reasons.

- even without being touched, over time the block may warp back to let the inner core become straighter

- after much of the cherry is carved away, it is much more likely that this will happen

- the cherry in some places is so thin that the chisels will penetrate to the core - very bad for them to cut through that layer of brittle and hard glue

- it is unacceptable to have the wood supplier think that I think this is acceptable ...

There are four of them warped to such an extent that I will not use them. Back they go. In the meantime, I'll start work with the others ...