Posted by Dave Bull at 2:05 AM, January 8, 2012 [Permalink]

With the Hanga Treasure Chest : Mystique of the Japanese Print series now in the home stretch, it is of course (past) time to do some serious planning for the next one.

Planning a new series means thinking not just about prints and designs, but of course the peripheral materials too, including the storage system. The system I devised for the original Treasure Chest, which combined storage and display in one unit ...

... was very successful, and the case for the Mystique series grew out of the same concept.

Now if (heh!) I were to be making another set of prints on a similar scale - desktop display size - I would have to decide either to use one of those two case designs, or come up with something new. I was mulling these issues over while I was carving yesterday morning, and had an inspiration for a way to make a case similar to the current Mystique model - of course combining storage and display - but which moved it forward somewhat. Call it Mark II, if you will.

I thought about it off and on during the day, and after the evening carving session was done, even though it's really getting ahead of things, I couldn't resist having a go at building a sample. I didn't actually pull an 'all-nighter', but the sky was starting to get a bit light by the time I finished! Here are some photos of the results:

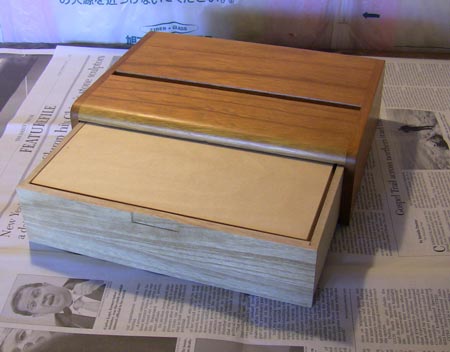

To start with, here's the case for the current Mystique series - made of light-weight paulownia wood, in a two-tone stain:

Most of you have seen how it works; the drawer slides open ...

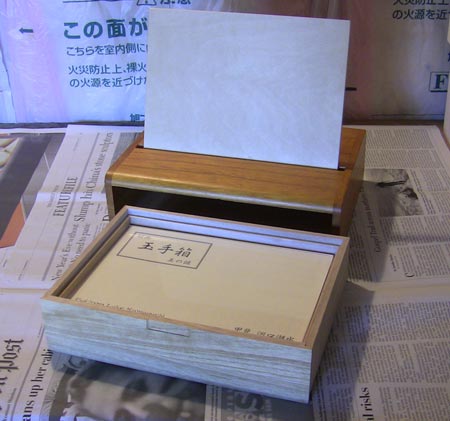

... revealing the stack of prints inside, along with a wooden stand and an acrylic cover sheet:

With the stand in place, it all looks like this on your desktop:

And a very nice little item it has turned out to be. Although some people have expressed reservations at my choice of a two-tone finish, that is a trivial point. More credible reservations have been expressed about the drawer concept - it is difficult to open when you want to (you have to pick up the whole box to do so), and it tends to slide open unwantedly when you are moving the box around.

The new Mark II addresses these concerns. Rather than make this new sample from scratch, I started with one of the Mark I cases (a dented and scratched one), took a saw to it, and disassembled it into its component pieces. Here are the bits I then trimmed off and tossed aside:

... along with the shavings from planing other parts to a new dimension (paulownia planes like butter!):

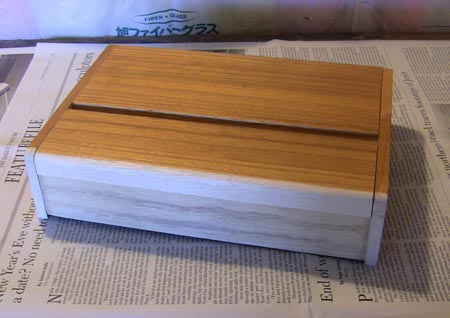

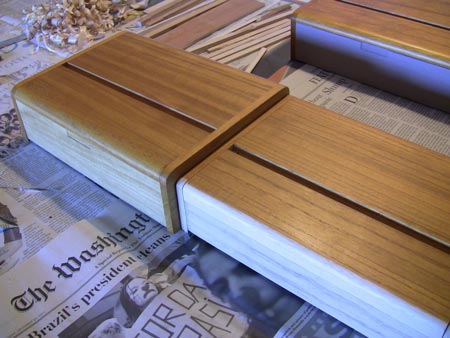

I then re-assembled the components in a completely new way, and it now looks like this - quite similar on the outside:

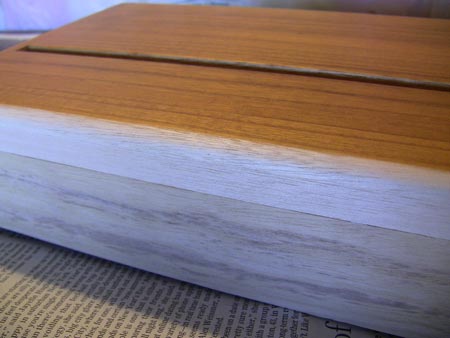

Note that I don't have any of that same wood stain here, so these photos show white bare wood in the spots where I have cut and re-shaped the parts. If we do produce this thing, it will of course be stained and varnished properly (and probably no two-tone this time, I think).

Here's how it opens:

Isn't that nifty! It opens easily when you want it to, and yet will never open itself by accident! Once the wooden stand and acrylic sheet are in place, it looks similar to the original model:

Putting the two models side-by-side, you can see that the new one is more compact in both height and depth (the width is unchanged), and yet it is interchangeable with the same print mats, stand and acrylic cover as the Mark I.

And there are no more 'drawer' problems!

There is, however, one more major consideration. The workshop who produced the Mark I cases does not seem particularly interested in doing any more work for me (as in, they are not replying to my emails!). The margins were pretty thin for them last time (not only them!), and I guess I was pretty 'noisy' about the quality of the work. So I am facing the prospect of having to make these in house.

Now making 200 of these would be fun, for sure, but it would need a pretty major investment in tools and jigs (my own home-made table saw just doesn't have the tolerances necessary for this kind of work), not to mention the time it would take.

Have to think about this for a while ...