Posted by Dave Bull at 9:38 PM, November 28, 2012 [Permalink]

Judging by our silence, you might suspect that nothing much is going on here these days ...

Hah!

I have no way to 'measure' it, but for these past couple of months, I think I've been busier than I probably ever have been up to now. Taking the decision last year to expand my business has turned everything completely upside down, but it seems that there is no turning back now. In any case, Mokuhankan business belongs over on the other blog; here on the RoundTable we should stick to news about my 'own' work.

Of which there is still none at the moment!

Actually, there is. I have now begun work on my studio new year print, and this might be of interest. As regular followers know, I do nearly all my carving on yamazakura, the Japanese mountain cherry. It's hard wood that allows fairly fine lines to be cut, but not so hard that it won't absorb water properly at printing time.

But I occasionally want a wood that is capable of finer work, and for those times, I use tsuge, boxwood. If the area in question is small, I inlay a piece of boxwood into a normal cherry block, but I sometimes want to cut an entire design in boxwood. In that case I use a piece like this:

I get these blocks from Woodlike Matsumura, who makes them for me kind of under protest. The boxwood is very difficult to work, and they end up tossing out many of the blocks before they can even get them shipped to me. And once I get them here, I don't dare use them straight away, because at least half of them develop a fatal defect of one sort or another during their settling period.

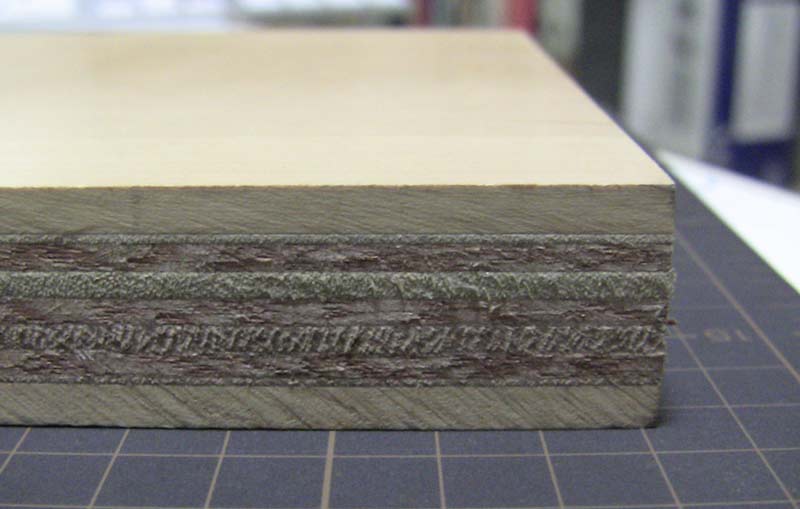

Here's an example; this one - which is the usual laminate of box and plywood core:

... began to come apart after a few months on the shelf:

The internal stress in the boxwood is so strong that it has separated the layers of the plywood itself.

Matsumura-san and I discussed ways that we can reduce the waste (and minimize the risks of this happening to a block after carving, which would be a disaster), and for some blocks that he sent to me recently, he tried thinning the boxwood layer to around 2mm:

The thought is that the thin layer won't be able to develop enough strength to pull itself off the core. We'll see.

Anyway, after a few months it seems fairly stable, so I decided to use one of these test blocks for the upcoming new year print. As always, I can't show you the design for this before the release date of the print (Jan 1), but here are a couple of closeups. The wood is not as hard as I would have liked, but it is very smooth indeed, and carves to a very nicely dressed edge ...