Posted by Dave Bull at 2:47 AM, April 23, 2012 [Permalink]

I haven't been reporting on the progress of the case construction over the past week, both because I myself was busy with making the print itself, and because Lee-san hasn't been here, as he's got 'other things to do' these days ... Because we weren't able to offer permanent full-time work, he of course has had to keep other options open, and has gone off to do something else. He'll be back for the odd day here and there next month.

So that leaves just me ... (and, as we will see further down the page ... some more faithful helpers!):

The router table I built is getting a huge amount of work making these parts. This is a new tool for me, and when planning what I would need for this project I hadn't even considered such a thing at first, assuming that a table saw would do most of the heavy lifting. But after the table saw that I ordered turned out to be such a dud, I studied up, learned about this 'new' way to use a router, and since then, this has become the 'go to' tool for almost any job we can think of. I'm never going to do without one again!

Here it is, putting some rabbets on a stack of 100 side pieces. It's no more fooling around - I'm making a batch of 50 cases this week, do or die!

Over the weekend, while dressing stock for all the smaller parts, I also laid up the laminated sections for 50 case tops, setting a timer for the glue set each time I did one, then moving over to other work before coming back to do the next one when the timer rang.

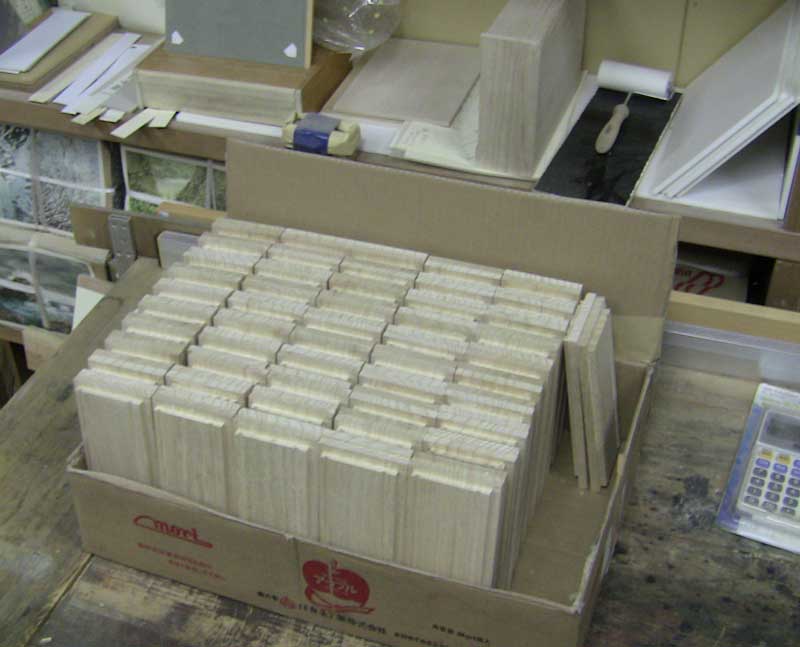

And here are those 100 side pieces ...

They are quite complicated little pieces, with rabbets all around, and two slots.

But after the basic rectangular piece is ready, it still takes 10 cuts to make these. The paulownia is extremely fragile, and I had to do shallow rabbets first, then deepen them in stages, as the wood would simply shatter or chip out if I attempted it in one go, no matter how I varied the speed/pressure of the feed.

Meanwhile, over in another corner of the shop, the previous batches of cases - the early trials, and the first run that Lee-san started last week - are now approaching completion, getting the final dress-up before the stain/lacquer goes on.

As you can see, with our entire printing team now occupied here in the woodshop, there isn't any printmaking at all getting done here this week ...

(Actually, that's not completely true. Lynita-san, if you are reading this, you should know that Fujii-san is doing just fine, and completed some nice work over the weekend. I'll post about it soon, when I get a minute!)