Fletcher - Woodblock Printing : Chapter III

Wood-Block Printing

F. Morley Fletcher

CHAPTER III

Description of the Materials and Tools required for Block-cutting

The wood most commonly used by the Japanese for their printing-blocks is a cherry wood very similar to that grown in England. The Canadian cherry wood, which is more easily obtained than English cherry, is of too open a grain to be of use. The more slowly grown English wood has a closer grain and is the best for all the purposes of block cutting and printing. Well-seasoned planks should be obtained and kept ready for cutting up as may be required.

When a set of blocks is to be cut for a given design, the size of the printing surface of each block should be made equal to the size of the design plus 1 inch or, for large prints, 1 1/2 inch in addition longways, and 1/4 or 1/2 inch crossways. The thickness of the plank need not be more than 5/8 or 3/4 inch.

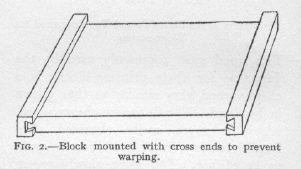

It is best for the protection of the surfaces of

the printing blocks and to prevent warping, also for convenience in

storing and handling them, to fix across each end a piece of wood

slightly thicker than the plank itself. These cross-ends should be

mounted as shown in fig. 2.

It is best for the protection of the surfaces of

the printing blocks and to prevent warping, also for convenience in

storing and handling them, to fix across each end a piece of wood

slightly thicker than the plank itself. These cross-ends should be

mounted as shown in fig. 2.

Both surfaces of the plank should be planed smooth and then finished with a steel scraper, but not touched with sand-paper.

It is understood that the face of the plank is used for the printing surface, and not the end of the grain as in blocks for modern wood engraving.

The tools needed for cutting the blocks are the following:

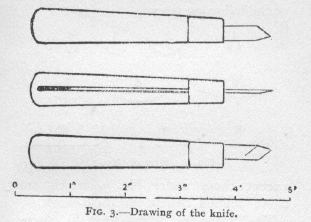

1.THE KNIFE

With this knife the most important and delicate work is done. All the lines of the key-block as well as the boundaries of the colour masses are cut with it, before the removal of intervening spaces.

The blade lies in a slot and is held tight by the tapered ferrule. This can be pulled off by hand and the blade lengthened by pulling it forward in the slot.

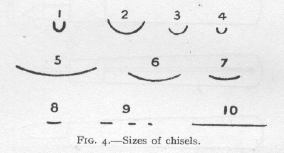

2. CHISELS

These are used for removing the wood between the

cut lines or colour masses, and should be ordinary carver's chisels

of the following sizes: except those under No. 9, which are

short-handled chisels for small work.

These are used for removing the wood between the

cut lines or colour masses, and should be ordinary carver's chisels

of the following sizes: except those under No. 9, which are

short-handled chisels for small work.

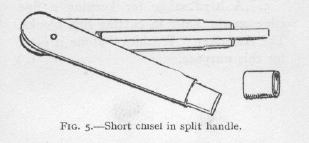

The Japanese toolmakers fit these small chisels into a split handle as shown in fig. 5. The blade is held tightly in its place by the tapered ferrule when the handle is closed, or can be lengthened by opening the handle and pulling forward the blade in its slot. In this way the blade can be used down to its last inch.

3. MALLET

This is needed for driving the larger chisels.

These are all the tools that are needed for block cutting. For keeping them in order it is well to have oil stones of three grades:

- A carborundum stone for rapidly recovering the shape of a chipped or blunt tool.

- A good ordinary oil stone.

- A hard stone for keeping a fine edge on the knife in cutting line blocks. The American "Washita" stone is good for this purpose.