N

making the first wood-engraving we went to an extreme in simplicity.

It does not always follow that the simplest and most primitive

process is the best, even if good craftsmen can do fine work with few

and simple tools. On the other hand, one can get himself hopelessly

entangled in engraving paraphernalia and methods. A need for a few

refinements may be felt. For one thing, we had difficulty in telling

which part of the surface of the block was cut and which uncut; the

surface is so much like the subsurface that it is something of a

strain to tell which is which. This trouble may be overcome by

constantly brushing dry oxide of zinc over the cuts as they are made,

or changing the color of the block at the surface before commencing

to cut. Then every slice that is removed exposes the natural color of

the wood, which would be of sufficient contrast to the discolored

surface to make the areas that have been cut easily evident.

N

making the first wood-engraving we went to an extreme in simplicity.

It does not always follow that the simplest and most primitive

process is the best, even if good craftsmen can do fine work with few

and simple tools. On the other hand, one can get himself hopelessly

entangled in engraving paraphernalia and methods. A need for a few

refinements may be felt. For one thing, we had difficulty in telling

which part of the surface of the block was cut and which uncut; the

surface is so much like the subsurface that it is something of a

strain to tell which is which. This trouble may be overcome by

constantly brushing dry oxide of zinc over the cuts as they are made,

or changing the color of the block at the surface before commencing

to cut. Then every slice that is removed exposes the natural color of

the wood, which would be of sufficient contrast to the discolored

surface to make the areas that have been cut easily evident.

A wash of Chinese white, or a paint made by mixing oxide of zinc with white of egg, is put on the block with the fleshy part of the hand. The zinc mixed with water and glue is a very poor substitute. The coating ought to be very thin for otherwise it may flake off and cause more or less trouble in losing the finer details of the drawing not only in engraving but in printing; or the drawing ink may peel off as it dries. It always does when glue is used as a binder for the coating mixture. It might be advisable to test the coating with ink marks. If the marks peel, the surplus coating should be removed with a damp rag. When dry it is ready for the drawing which had better be strengthened with drawing ink. Now, as we may want to whiten the cut parts later on to get a better idea of what a proof will look like, the white surface coating will cause a little confusion. To remedy this a wash of green or blue oil paint or printing ink - well thinned with turpentine or gasoline - is run over the drawing before commencing to cut the block. If you were to put this stain on the uncoated block it would penetrate the surface, and so defeat its purpose. If but one job of the coating were made by putting blue, green or black stain on the block there would be a little difficulty in seeing the drawing before it was inked. With the darkened surface the effect of the finished print is approximated as the cutting advances.

In the end you may conclude that the best procedure is to make the drawing directly on the block with either Chinese or water-proof ink, and dust in the powdered zinc as the cutting proceeds. John Jackson, in his book on the art, complained that the coated block was more difficult to work on than the uncoated because the uncut coated surface looked so different from that which had been cut. There is something of danger in the coating being dissolved by the cleaning fluids, and filling the finer white lines, so it will be wise to print off an edition of proofs in as few sessions as possible. I mention the coating scheme because I have found it an advantage, but as in all things one pays his money and takes his choice.

Another approach is to blacken the surface of the block entirely with either water-proof ink or diluted printing ink and indicate the design with Chinese white.

Any water put on the surface of the block will tend to raise the grain of the wood and of course roughen the surface. For dainty work this is likely to prove to be a good deal of a nuisance, if not an unmitigated evil. To overcome this effect when applying a water-color paint to a block, it may be given a good coating of boiled linseed oil with turpentine added, so that it may the better enter the pores of the wood, and dry more quickly. It may require at least a week to dry sufficiently to take the white coating. Apply the oil to front and back. Linseed oil is one of the great many commodities which have deteriorated in quality with the development of our banker's civilization. Sometimes it will not dry for weeks and weeks. When it does the surface will have to be rubbed with dry zinc white or magnesia powder before applying the water color, as the oil naturally repels water. A soft flat brush about three-quarters of an inch in width might be used in laying on the coating. And remember to get it as thin as possible.

The oiled block has the advantage of being pretty well immune to climatic changes. Blocks are very apt to warp in either excessively dry or wet weather. Another advantage, especially before the oil has become bone dry, is the easier cutting and the reduced friability of the wood cells.

It looks like a good deal of bother to first oil a block, then to rub it with dry powder, then to paint it with a white water color, and after the drawing is made and inked, to stain it dark, and finally to dust powder into the cut surface. It is. But this technique is not absolutely necessary. It is merely to enable one to tell more readily where he is - the gasoline gauge in a car without which the car will run just the same.

If one prefers to work on the uncoated block, besides using the zinc powder to brush into the cuts, the surface may be darkened by rubbing printing ink over the finished parts - using the tip of the finger and very little ink at a time.

Remember that the design reverses when it appears as a print. It is well to study the drawing carefully with a mirror before commencing to cut - making sure that the warrior has his sword on the proper side, and maps and celestial bodies are all in the right relation.

Take time when cutting. Make haste slowly and thoughtfully. A block may be 'plugged' if one has been too impetuous, but plugging is a fearful time-waster. If in doubt in the matter of removing some of the area on the block, make two prints from it, and cut out or otherwise modify the questionable matter in one print and compare it with that of the other, and act accordingly. Except by plugging, a block cannot be modified much once the surface is cut away.

It is possible to remedy an inadvertent cut or a mistake, and to some extent, to build up a surface that has been cut. Wood-flour, preferably ground oak, is mixed to a rather stiff consistency with LePage's water-proof cement (or John Collin's China cement - both of which may be bought at the 5 and 10 cent stores). A little of the unmixed cement is first touched to the wood as a priming for the mixture, which is then pressed in. It dries rather quickly. It will be better to go over the surface again after the surplus fiber has been scraped down. It is a fairly good imitation of wood.

The procedure given applies specifically to end-grain maple, which is recommended for ordinary use. Writers on the art invariably specify the use of box wood. There is no objection to it except that of cost; it runs from twice to seven times that of end-grain maple. The cheaper grades of box are very likely to break apart in press or sometimes in transit, for generally such are not tongued and grooved when the blocks are made up. As there are no large box trees the larger blocks are made up of small pieces glued together. The American variety is not considered as good as the Turkish, and the Turkish not as good as the English. The Turks are careless in cutting down trees so that the blocks are likely to be flawed. The best wood has a clean unmottled yellow color. I have seen it mentioned that box wood is preferable to that of any other because worms will not eat it. It seems it is a poison, and you are hereby warned not to munch the chips. I do not think the danger of voracious worms is very great. Not much if any wood of the most delectable quality will be chewed off a block in the interval between the first cutting and the pulling of the last signed proof. After that time worry had better be directed against bookworms.

It will be necessary to keep blocks out of the weather and direct sunlight, otherwise one has to contend with warping and checking. An excessively dry place is almost as dangerous as a damp one. If a block shows signs of checking or cracking - caused most likely by being in the sunlight - soaking it from the back with boiled linseed oil is the only thing I know of to stop it. The cracks could be filled with the wood-flour mixture. A warped block, if of one piece, may be straightened by putting the concave side on a wet blotter, making sure the blotter is in contact with the entire surface. The process cannot he hastened much. The top or convex side may be exposed to the sun at the same time, but one must keep his eye and mind on the job. The more slowly a block is restored to its pristine straightness, the less danger of checking or cracking. Obviously, a warped block should not be put under pressure in a printing press. A block ought to be worth a damp blotter if it is worth anything. If the warped block is one that was made up of a number of pieces, rectification is not so simple. The convex side is the one that has absorbed moisture. Laminated (ply wood) blocks may twist. A coat of linseed oil on the face, after it has been cut, and shellac at the sides and bottom of the block will exclude moisture. The core of laminated wood is likely to be the cheapest and softest and thus the most porous so that linseed oil would be absorbed too readily. It is better to anticipate trouble in this work; a good head-light is always more useful than a tail-light.

Paper for printing can be of any soft, tough kind; that is, if burnishing be the method of printing. For printing on a press almost any kind will do at first. For a while I used the stuff that bread was wrapped in, before fancy bread wrappings were glorified by ad-men. Fine papers can be had at the Japan Paper Company. Yedogawa Tissue, white and in size 22 x 31 inches, Kitakata No. 3966, cream colored and in size 16 x 21, and the thinner vellums are all good for burnishing.

A marble slab, say 15 x 18 inches makes a fine inking slab. Failing that, a sheet of plate glass is next best. When mixing colored inks a piece of white paper ought to go under the glass. And under that it is not a bad idea to have a sheet of corrugated cardboard to keep the glass on an even keel. The glass, paper, and cardboard could be fastened to the table with a few drops of glue if the shifting of the slab induced by the roller bothers.

I do not think much of colored inks for monochrome work. In the end, they all come pretty close to being an affectation. Black and white is a beautiful combination.

The graver known as a tint tool is very useful. It is thin across the blade, which enables the artist to dig deeply into the wood without appreciably affecting the uniformity of the lines, or in other words, it is easier to keep under control because it requires less. One tint tool should answer fairly well for ordinary purposes. Muller offers them with edges from No. 1 making the finest white lines to No. 12 making a white line about 1/25 of an inch wide.

There

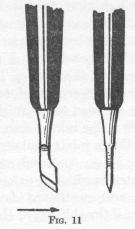

is no particular reason for holding to the conventional handling of

the gravers, or for that matter, to the conventional tools. I have

often used a ground-down manicure knife much like a ruling pen in

mechanical drawing, for incising thin straight lines, See Fig. 11. My

favorite tool for a time was made from a one-eighth inch drill rod.

It was straight except where it was necessary to round the bottom of

the lip to make the cutting edge. With this tool one can not only

make a cut the width of the lip, but by holding it perpendicularly

and working the cutting edge side-wards with the fore finger of the

other hand one can make the narrowest of scratches.

There

is no particular reason for holding to the conventional handling of

the gravers, or for that matter, to the conventional tools. I have

often used a ground-down manicure knife much like a ruling pen in

mechanical drawing, for incising thin straight lines, See Fig. 11. My

favorite tool for a time was made from a one-eighth inch drill rod.

It was straight except where it was necessary to round the bottom of

the lip to make the cutting edge. With this tool one can not only

make a cut the width of the lip, but by holding it perpendicularly

and working the cutting edge side-wards with the fore finger of the

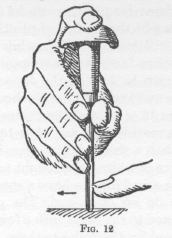

other hand one can make the narrowest of scratches.  The fore finger of the other

hand is a mighty useful tool when it is brought into co-operation

with the cutter - using it principally as a fulcrum. See Fig. 12. For

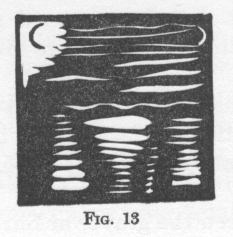

specimens of cuts made in this manner see Fig. 13 at the bottom of

the page.

The fore finger of the other

hand is a mighty useful tool when it is brought into co-operation

with the cutter - using it principally as a fulcrum. See Fig. 12. For

specimens of cuts made in this manner see Fig. 13 at the bottom of

the page.

A cheap tooth-brush is good for brushing dry zinc white into the incisions during the process of engraving. By a cheap tooth-brush I mean one that is not advertised and thereby is without virtue as a tooth cleaner - like the 5 and 10 cent store variety that has no corrugated bristles. A nail brush also offers possibilities. It will be better to reserve a brush for cleaning off printing ink, and not use it for dusting because of the danger of filling the finer white lines. I use a long-handled bristle brush about 3/4 of an inch in diameter to dip into a bottle of gasoline. The print-trade people put out a special brass-wire brush at $2.00. It is too harsh for some woodcuts. There is also a special gasoline container that automatically closes when not in use. That costs something like $2.00, too.

The

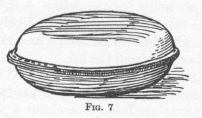

embryo woodcutter may think that because almost all the engravers

have used a sand pad he ought to get one instead of using the clumsy

bench hook or a heavy congressional report. The pad is evidently a

much more useful instrument, for the block can be manipulated easier

on it; it acts not only as a rest but as a pivot. See Fig. 7. The

conceit will cost him $2.20 to $2.50 for a six-inch pad. It may be

had at Paulson's or at Muller's. There is a more elaborate holder on

the market used by jewellers and metal engravers for holding spoons,

watches, rings, etc. It will cost from $18.00 to $48.00 to realize

that ambition. A try-square and a draftsman's triangle are useful

implements.

The

embryo woodcutter may think that because almost all the engravers

have used a sand pad he ought to get one instead of using the clumsy

bench hook or a heavy congressional report. The pad is evidently a

much more useful instrument, for the block can be manipulated easier

on it; it acts not only as a rest but as a pivot. See Fig. 7. The

conceit will cost him $2.20 to $2.50 for a six-inch pad. It may be

had at Paulson's or at Muller's. There is a more elaborate holder on

the market used by jewellers and metal engravers for holding spoons,

watches, rings, etc. It will cost from $18.00 to $48.00 to realize

that ambition. A try-square and a draftsman's triangle are useful

implements.

Whenever possible get tools that are used in the trades, as a matter of economy. For example: A T-square twelve inches long with a 'brass-head' will cost you $3.00, presumably because it is called an 'Engraver's T-Square.' A machine quite as useful and likely to be more accurately made, is the try-square used by carpenters, which sells at 50 cents or so. Many dealers when doing business with artists seem to assume that they are all rich, and take it for granted that everything an artist produces fetches enormous prices, overlooking the fact that almost always an artist has to be a dead one before he can fetch an enormous price.

|

try- or T-square |

Yedogawa Tissue |

|

cheap tooth-brush |

Kitakata Tissue No. 3966 |

|

triangle |

Shidzuoka Vellum No. 0 or 1 |

|

soft flat brush |

magnesia powder |

|

tint tool |

wood-flour |

|

sand pad |

LePage's water-proof cement |

|

|

white of egg |