To make the 'tsuna' (the inner coil) of the baren, the type of bamboo skins that are commonly used for wrapping food are not suitable. The best type for baren-making is the skin of the kashiro-daké (or shirakawa-daké, one kind of the common bamboo known as ma-daké), a product of Chikugo (the traditional name for the southern part of Fukuoka Prefecture). If you want the best of the best, you should use the naka-kawa (skin which has come from near the middle of the bamboo stem) rather than the moto-kawa (skin taken from close to the root) or the ura-kawa (skin taken from near the tip of the plant), and it is also important that skins which have fallen during the period from the middle of June to the middle of July be selected. Kashiro-daké is not often seen these days, but in former times it was frequently used for the Japanese sandals known as nanbu-omote. Kashiro-daké is quite different from typical bamboo skin. It has very few of the 'speckles' that are characteristic of most bamboo skins, and it has a whitish colour. The best skins have almost no speckles. A prime characteristic of this skin is the strength of the fiber. As both sandals and the baren are subject to constant abrasion, it is essential that the material chosen should be tolerant to friction. People say that if a professional printer uses a well-made baren skillfully, it will last his lifetime, a good indicator of just how strong the skin of the kashiro-daké is. The best kashiro-daké is said to be that which comes from the Chikugo region, but it is not found only there.

Now, for the actual making of the tsuna. The first step is to put the skin of the kashiro-daké into water to soften it. There are various opinions about how long the skin should remain in the water, but Mr. Kobayashi the printer says that one week is the standard; there is no concern that it will become too soft. It is important though, that the water be changed every day. Perhaps actually it could be placed in the running river, as are the materials used for making paper ...

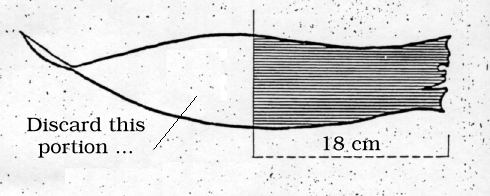

The skins are now placed in water for a time to soften them, and they are then removed from the water, and wiped on both sides carefully to dry them. When removing the skins from the water, if you find some that are very soft and easily broken, discard these immediately, as they are too immature to be of any practical use. Then, cut 15~18 cm of each skin (from the base end) and throw away the rest. This part contains the strongest fibers.

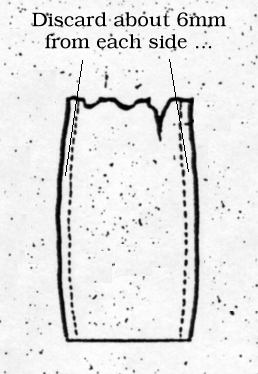

Then tear away and remove the thin soft portion at each side of the skin. The width of the part you should take away may range from less than 1 cm to almost 2 cm. Never hesitate to throw away such soft parts.

No portions that are even slightly soft should remain. As the quality of the skin determines the efficiency of the completed baren, you should use only the best of the skins you have stringently inspected. Perhaps you will check 10 skins? 20 skins? They are nothing! Don't be stingy!

Then tear the parts that were carefully screened into strips of about 1.5 to 2.5 cm in width. Now at last we are approaching the crucial point. Be ready and listen to it carefully.