Wood Engraving

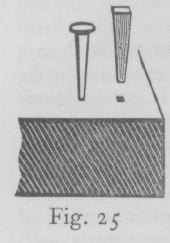

If some small mistake has arisen such as a deep bruise, false cut, slip, etc., it can be made good by plugging, that is, by the insertion of a new piece of wood where the mistake has occurred. This requires skill and care, for the new piece of wood must fit in exactly, otherwise a white line will show all round it. For very small plugs the simplest method of making a hole is to get a carpenter's nail, round or square type, according to the shape of the plug required, file the sides to the right size and flatten the bottom, finally getting the edges and bottom. sharp and smooth on the oil-stone. Drive this into the wood, about 1/16 to 1/8 of an inch according to the size of the plug. Take the nail out again by a straight pull to avoid bruising the sides, and if the nail has been properly shaped, a clean hole with sharp edges will be the result. Into this hole insert a piece of boxwood, trimmed to exact size by means of a flat tool or chisel, then gently hammer with a piece of wood until the bottom of the hole is felt. To dip the end of the plug into thin glue or gum before insertion will help to keep it fast, but small plugs accurately trimmed will hold without glue. For larger plugs glue must be used.

Through

a thin piece of card cut a hole large enough to allow the head of the

plug to protrude, place it in the block to protect the engraving,

then cut off the projecting head close to the card with a fine saw.

By means of the scauper and card, always cutting towards the centre,

lower the remaining projection until nearly level with surrounding

surface, and finish off with the chisel laid flat on the block. An

excellent tool with which to get the plug level is a fine tint-tool

laid on its side and used as a chisel, chisel or tint-tool being used

in a slicing movement and not driven.

Through

a thin piece of card cut a hole large enough to allow the head of the

plug to protrude, place it in the block to protect the engraving,

then cut off the projecting head close to the card with a fine saw.

By means of the scauper and card, always cutting towards the centre,

lower the remaining projection until nearly level with surrounding

surface, and finish off with the chisel laid flat on the block. An

excellent tool with which to get the plug level is a fine tint-tool

laid on its side and used as a chisel, chisel or tint-tool being used

in a slicing movement and not driven.

Two or three plugging nails, made ready and kept for the purpose, will be all that are required for smaller plugs. The holes can also be made by drills such as are used for fretwork. Larger plugs must be scauped or chiselled out, taking care that the sides go straight down and that the edges are without a bruise. The larger the plug, the deeper must be the hole, the depth for large plugs being half-way through the block. Plugs on the extreme edge of the block require more care but the difficulties can nearly always be overcome by a little ingenuity. A drop of water placed on a bruise will often bring it to the surface again. Hot water is still more effective, while, if the bruising is deep and general, steaming the whole surface is the best method though it makes the wood rotten and disagreeable to cut on afterwards.